3KD is one of TECNIDEA CIDUE’s patented products. Before describing the features of this item and explaining its technical details, we should give a brief overview of chain transmissions and their usage restrictions.

Transmission:

Traditional chains can only operate on a flat surface. For this reason, if a motor drive has axes that are not perpendicular to the work surface of the chain, suitable devices need to be used such as angle transmissions, conical pairs and reducer shafts to transmit motion to the other parts. The main drawback of chains is their two-dimensional nature and the fact that parts cannot be reached in space regardless of their position. If there are devices on different surfaces, a chain is needed for each drive surface, along with a shaft, a support and device for shunting movement onto the surface where the chain is located.

TRASPORTATION CURVES:

This form of transportation can only be carried out using chains fitted with increased backlash between their constituent components (plates, pivots, bushings and rollers) so that the chains can form a curved trajectory on the surface on which they are positioned and therefore also connect parts not arranged in the same direction.

In any case, the curves that these chains can create make it possible to connect parts positioned in different directions, although they must be located a short distance away and have a detrimental effect on the performance of the transmission and its life, with significant wear of the conveying shoulder.

The increased backlash between the different chain elements produces very high levels of friction between both the internal and external plates and the chain and sliding guides. In the same way as for the chains used in the transmission, movement can naturally only be developed on a single level.

The main objective of 3KD multidirectional chains is to overcome the limits of the applications of traditional chains, providing customers with a transmission device or interlocking flexible transportation device that can bend in any direction in space.

3KD can achieve these aims thanks to its structure; it consists of a series of concatenated elements aligned at right angles to each other, each one of which is connected to its adjoining elements by hinges and is therefore able to rotate around the axes of these hinges (each hinge is crooked with regard to its two nearest axes).

The components used for the assembly of 3KD are:

• Grid

• Bushings

• Rollers

• Pivots

• Washers

As it can be seen, the features of the product in question are not very different from those of traditional chains; what is different is their shape and degree of freedom in remaining unrestrained after assembly. The resulting structure is an interlocking device formed by a series of aligned concatenation parts, each of which is connected to nearby parts by hinges and can rotate around the axes of these hinges.

3KD is a device for transmission and interlocking flexible transportation. It can be used, for example, to transmit motion between components of mechanical devices; in the simplest of cases it can enable transmission between the gear shrunk-on the motor shaft and the corresponding gear fitted on the driven shaft.

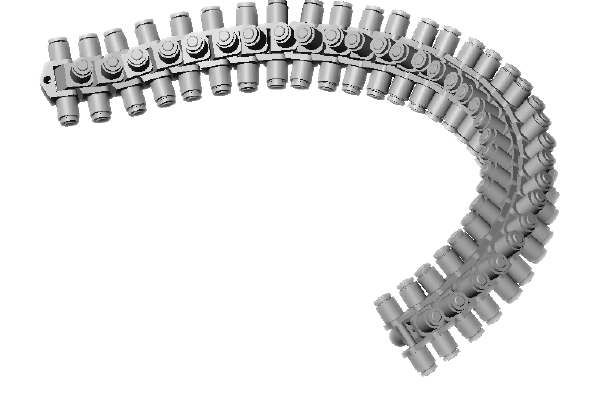

Here follows an overview of the transmission device and its constituent parts:

As the following table shows, the multidirectional chain can support greater loads than a standard chain with the same pivot diameter.

This greater resistance to traction is closely linked to the structure of the 3KD chain; while standard chains basically have two points on which the whole load can be placed, with a multidirectional chain the load is distributed over three points, thereby allowing greater shear strength and consequently enabling the chain to work with decidedly greater loads than traditional chains.

An especially interesting feature of this chain is the method used to lubricate its constituent elements so that it always has the right characteristics for adequate motion transmission. First of all it should be underlined that all 3KD segments are placed in an oil bath before being assembled as part of the chain lubrication process. As a result of the structure, while the chain is moving the lubricant only acts in one direction and only lubricates the pivots, bushings and rollers working on the toothed wheels; when the direction is subsequently changed, the lubricant re-enters the grid and lubricates the pivots, bushings and rollers that start working on the new gear pair positioned in the direction of chain movement. A fundamental role is played by the recess inside the grid, which is used to collect lubricant liquid, and the positioning of the washers, which close the chain and stop the lubricant from seeping out; together they guarantee both the achievement of top speed and a long life for the transmission. 3KD offers an interesting advantage here compared to standard chains, as the lubrication of the multidirectional chain is guaranteed for a long time without requiring any special outside intervention, while periodical intervention is needed with traditional chains to maintain an acceptable level of lubrication and make the transmission work properly. Another important feature of 3KD is that although it is an innovative product with unique characteristics, its design uses the same procedures and formulas used for standard chains.

In the way that it is designed, the chain has the big advantage of raising the concept of mechanical transmission from the two-dimensional to the three-dimensional. Indeed, designers can use this chain to indulge their imagination by planning machines of any shape and size; it will no longer be necessary to use devices to move the transmission to another level (for example with angle transmissions). The 3KD structure includes interlocking on the toothed wheel of the rollers outside the grid, meaning that only two sets of rollers work at a time while the other two sets, which are positioned perpendicular to them, are activated when there is a change in direction. Another important feature is that this type of chain does not require special toothed wheels; it was designed to use standard triple pinions without central teeth or a simple pinion welded with a crown ring.

For our customers, Tecnidea Cidue provides various sizes of chains characterized by the pitches of a standard chain, that is the distance between the axes of two consecutive rollers placed on the same plane. The distance covered by the production of multi-chain are:

TRASMISSION:

- 3/8” → 9.525 [mm];

- 1/2” → 12.7 [mm];

- 5/8” → 15.875 [mm];

- 3/4” → 19.05 [mm];

- 1” → 25.4 [mm].

TRASPORTATION:

- 3/4” → 19.05 [mm];

- 1” → 25.4 [mm];

- 1” 1/4 → 31.75 [mm];

- 1” 1/2 → 38.1 [mm];

- 2” → 50.8 [mm].

Another very important aspect of this chain is relative to the characteristics of the pinions required for a correct transmission of motion. These are of standard dimensions, in fact or using triple sprockets with the inner crown or lathed using a simple pinion welded to a crown, in this last case, the distance between the two sets of teeth will vary according to the size of the chain. This aspect is very important as it enables the final user of the chain to have elements already present on the market, then will enjoy a multidirectional chain using standard elements limiting the best costs.