Rubber suspension units produced by TECNIDEA CIDUE are mechanical items which take advantage of the elastic characteristics of rubber to be used in several applications with the purpose such as: “springs”, “shock absorbers”, “decelerators” and “oscillating supports”. Rubber torsional suspension units, with their simple structure and use, can be recognised for their high elasticity and ability to absorb impacts, shocks, vibrations and oscillations.

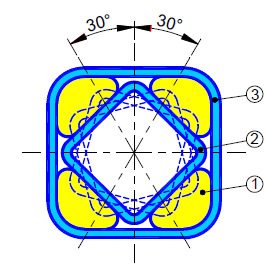

Key

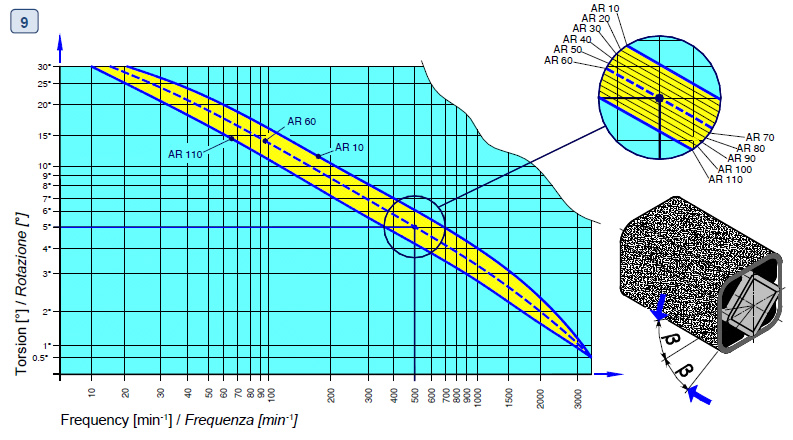

1: Natural rubber cylinders

2: Inner square section

3: External square section

With these products, designers can replace obsolete vibration-damping, oscillating, shock absorbing and suspension systems, avoiding expensive wastes of time and also reducing maintenance costs. Several applications take advantage of the same operating principle: the elastic deformation of four natural rubber cylinders (1), placed inside the space resulting from the coupling of two square-section elements (2 and 3) rotated by 45° respect to each other. The rubber cylinders are made by natural rubber, suited for use in these applications by placing particular additives and carrying out special chemical and heat treatments. The maximum admissible torsional angle between the two square sections is ±30° and is inversely proportional to the oscillation frequency. It is not necessary to use axial containment systems for the two square-section elements, since the friction of the prestressed rubber prevents them coming out in either of the two directions. The specific constructive system makes it a highly reliable, elastic and compact system with minimum room used, which permanently eliminates problems such as noise (there are no metal parts in contact) and pollution (there are no lubricants and wear is insignificant), with a notable reduction in running costs. Internal and external metal components, mainly of aluminium, steel and cast iron are assembled with natural rubber inserts. External tubes/parts are coated with a highly resistant paint which is the result of a oven paint at 200°C, all inner parts, in order to keep dimensional tolerances, are galvanized. The tolerances indicated in the catalogue refer to raw or galvanized profiles. All the products described in this catalogue can be used with temperature ranging from –40°C to +80°C. The nature and treatments to which the materials are subject, allow the use of these products under severe environmental conditions since they are insensitive to dirt and are very resistant to water and to the rays of the sun.

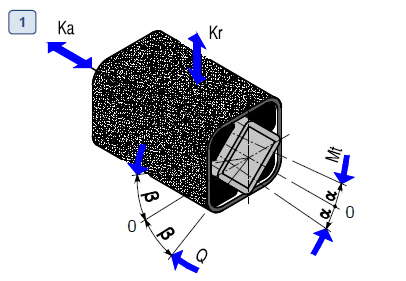

The VIB elastic elements are mainly used as torsion springs with a β maximum rotational angle of ± 30°.

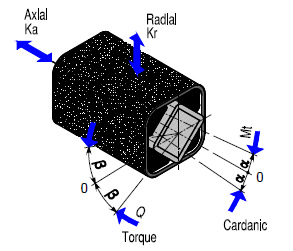

As highlighted in the drawing, the VIB elements can withstand 4 different types of stress:

Kr : Radial Stress Q : Torque

Ka : Axial Stress Mt : Cardanic stress

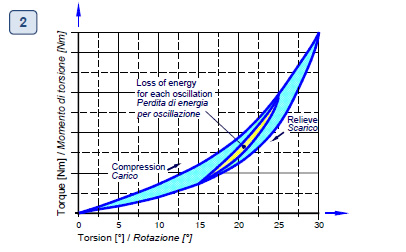

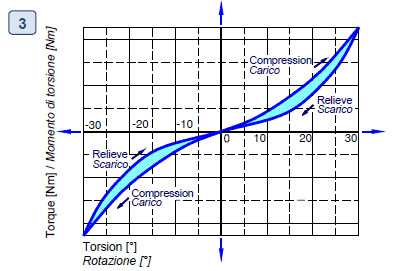

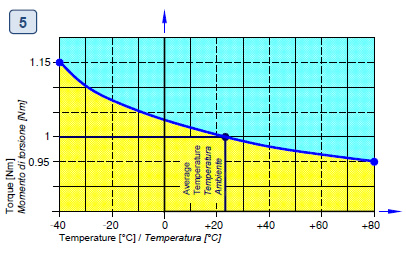

The shock absorption value is not constant as it depends on factors such as temperature and acceleration. The area between the loading curve and the release curve represents the loss of energy by oscillation. The capacity of the VIB elements to damp quickly the motion, decreases significantly the problems during the start-up and stop-down of the oscillating machines.

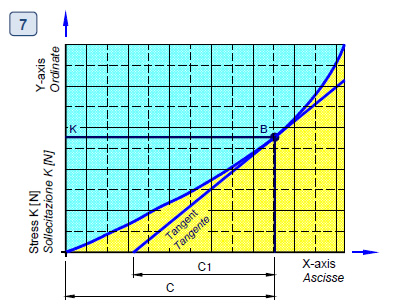

The special construction of the oscillating element allows to have progressive elasticity (as can be seen in the graph at the side) both in the loading and releasing phase. The torque is proportional to the length of the rubber.

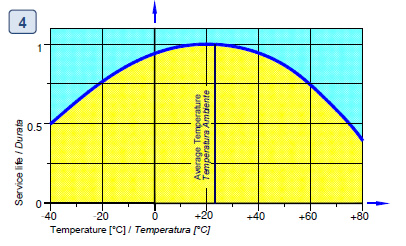

In order to keep unchanged over time the features of our elastic elements, the operating temperature should be as specified in the graph by factor 1. Every time the thermal factor varies, also the durability of the rubber changes and therefore the efficiency of the product.

The rubber used in our products has been designed to operate in a –40°C +80°C temperature range. If the temperature exceeds 80°C, mechanical resistance is reduced and the percentage shock absorption consequently increases at low temperatures and decreases at high temperatures. It should also be remembered that the real operating temperature is not the temperature of the surrounding environment, as the dissipation in the form of deformation energy heat, causes a further rise of the temperature

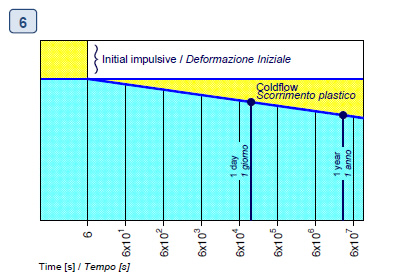

The graph at the side shows the long-term deformation of the rubbers used in VIB elements. The operating range varies by ±30° rotation and deforming load is as shown in the specific technical tables. As can be seen one day’s deformation is just some over half the deformation of an entire year of operation. The non-return memory of the rubber used in our products changes from 3° to 5° with respect to the resting position.

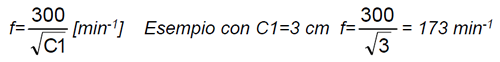

The approximate specific frequency can be obtained via graph and formula described below; if we know the value of the load K, we can easily obtain the distance of the C1 axis, obtained from the tangent to the curve at point B. [formula]

This diagram shows the ratio between the spring stroke and its own frequency.

EXAMPLE:

1 mm = 960 min-1 / 16,00 Hz

10 mm = 300 min-1 / 5,00 Hz

50 mm = 134 min-1 / 2,23 Hz

100 mm = 96 min-1 / 1,60 Hz

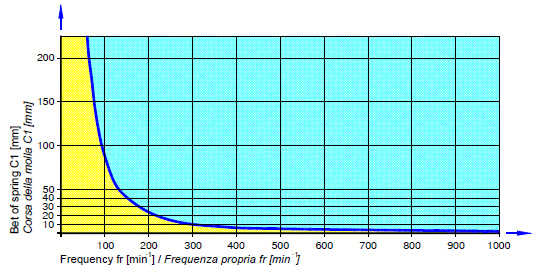

The diagram facilitates a quick determination of maximum frequency according to the oscillation angle and the selected oscillating element. The higher is the frequency the smaller is the oscillating angle.

EXAMPLE: An oscillating element AR 60 can be brought to a maximum frequency of 500 min-1 (8,3 Hz) with an oscillating angle of ±5°.

TECNIDEA CIDUE has spent many years researching, studying and developing the rubber we use to manufacture our products: CRESA, CIAO, VIB and MOTOR BASES. The core of these products are the natural rubber cylinders placed inside the spaces resulting from the coupling of two square-section elements. The great idea was to use them in various configurations, as a particular spring that, with the right excitation, absorbs or gives forces, adapting to all situations, modulating its capacity to absorb loads or release controlled or chaotic vibrations.

It has not been easy to get the current results that are a perfect balance between absorbed forces and released vibrations. The current rubber of TECNIDEA CIDUE allows the use over time of our products according to the value indicated in the catalogue, ensuring the operation, quality and duration. The special compound is the result of a developed and still developing evolution, it is only thanks to a strong cooperation between our partners (sales dept., technical dept., compound designers, extruders, workers etc) that we can manufacture high-quality products.

VIB items are made with modular elements in order to be used in several mechanical applications. All the elements work in an angle field included between +/-30° except some particular exceptions; in these cases a preloading system is used that allows, for example, to work in a rotation area between +7° and +30°. The large range of possible shapes can be applied in many industrial areas that, thanks to the different type of materials used (steel shape, aluminum shape and in stainless steel, iron and aluminum castings), allows the realization of technologically advanced systems. Metal components are always subjected to various finishing treatments that make them suitable to the different requirements of our customers. Natural rubber used has high capacity of absorbing shocks and oscillations because, when it is stressed by external exciting sources, such as vibrations, the energy of plastic deformation it is dispersed in the environment as heat. The grip features typical of the rubber, anyway, allows to it to recover fully the deformation suffered. VIB elastic elements thanks to their versatility are suitable to replace the traditional applications with systems to: Tension and Press, Cushion and Damp, Vibrate, Suspend and Support.

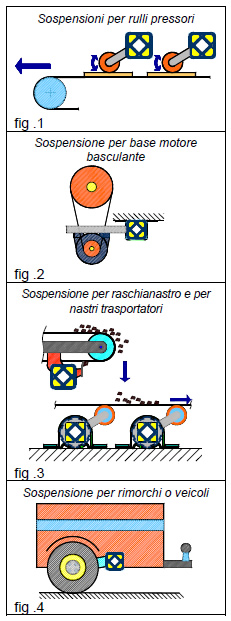

• System to TENSION and PRESS: This application replaces in a very efficient way the traditional executions with the springs and counterweights for the construction of automatic chain and belt-tensioners, pressure rollers (see fig. 1), tensioner ropes, control systems, downholders, guide for conveyors, etc.

• System to CUSHION and DAMPEN: In this case VIB are used to realize: stop bulkheads, support for oscillating motor bases (see fig. 2), vibration-damping supports, insulation of electrical panels, bed impact tables. The main function is to absorb shocks, vibrations and to damp the oscillations that propagate in all the machinery structures. This works in a noiseless, reliable and compact way.

• System to VIBRATE: With this technology, it is possible to move products without the use of mechanical shifting parts but only taking advantage of the weight itself of the conveyed material (see fig. 3). This system is very easy to realize and it complies with the strictest sanitary regulations, since there is no formation of dirt from operation wear. Possible applications are many: in addition to the conveyor suspensions, they must be mentioned all the systems necessary to feed or dischange materials, distribute, dose, screen, select and uniform all the products processed: we are speaking about vibrating screens.

• System to SUSPED or SUPPORT: These are particular vibration-damping systems that are used as alternative to the oscillating supports and they successfully replace the traditional mechanical systems as supports, bearings, bushings and suspensions, with an innovative technology that eliminates maintenance and make easier the constructions (see fig. 4).

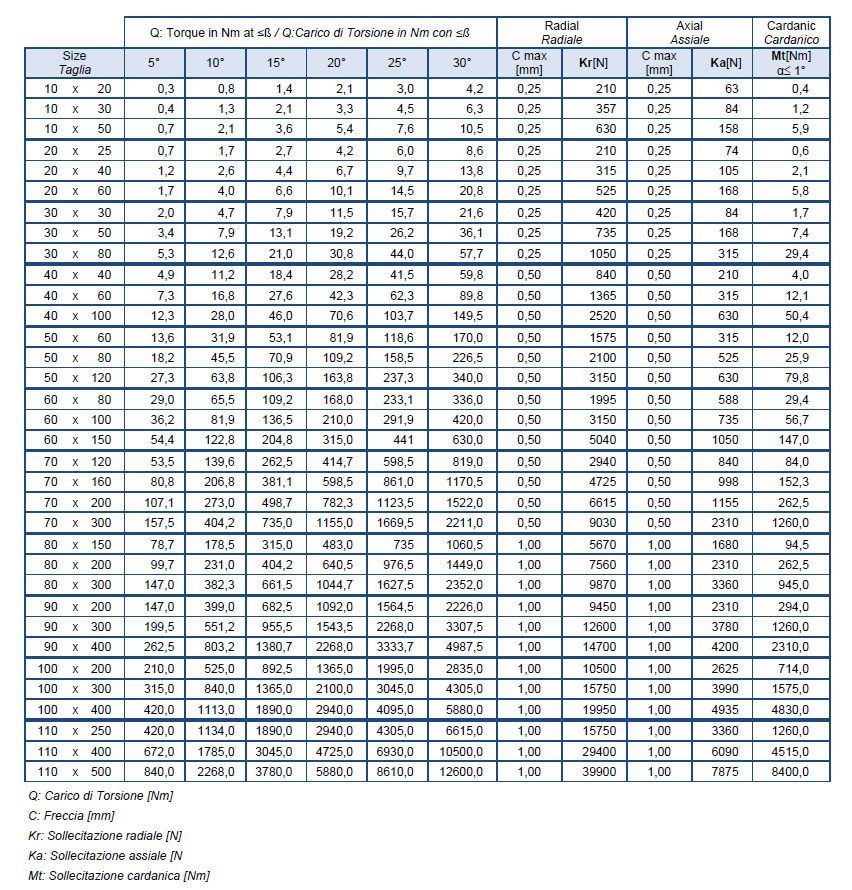

The values indicated in the table are valid for all VIB elastic elements type AR - AC - AD - AS. The intermediate values can be obtained by interpolating the reported data. In case of combined dynamic forces see chapter B. Consult our technical department if necessary.